Products Description

Alloy 600 (UNS N06600) is a nickel-chromium alloy that is specifically designed to be used in a wide temperature range, from cryogenic temperatures up to elevated temperatures reaching 2000°F (1093°C). It is known for its excellent corrosion resistance and versatility.Alloy 600 is non-magnetic and can be easily welded, making it convenient for various fabrication processes. It finds applications in a wide range of corrosion-resisting environments.The high nickel content in Alloy 600 provides excellent resistance to reducing environments, while the chromium content imparts resistance to weaker oxidizing environments. This combination of nickel and chromium allows the alloy to withstand a variety of corrosive conditions.Furthermore, the high nickel content of Alloy 600 provides exceptional resistance to chloride stress corrosion cracking, which makes it suitable for applications where exposure to chlorides is a concern.Alloy 600 is known for its unique combination of high-temperature resistance and excellent corrosion resistance. It is widely utilized in industries such as chemical processing, nuclear engineering, heat treating, and furnace components, where it is exposed to high temperatures and aggressive environments.

Applications

- Aerospace Components

- Chemical Processing – chlorination equipment, fatty acids, hydrogen fluoride, magnesium chloride, vinyl chloride monomer, sodium sulfide, titanium dioxide

- Food Processing

- Petrochemical Processing – catalyst regenerators

- Power Generation – nuclear components

- Pulp and Paper – abietic acid equipment

- Thermal Processing – baskets and trays, boxes, muffles and retorts, nitriding containers, roller hearths, vacuum furnace components

Standards

ASTM..................B 168ASME..................SB 168

AMS ...................5540

General Properties

Alloy 600 (UNS N06600) is a versatile nickel-chromium-iron alloy that be utilized in temperatures ranging from cryogenic up to 2000°F (1093°C) and for corrosion resistant service. The high nickel content assures the alloy will be virtually immune to chloride-ion stress corrosion cracking while also providing corrosion resistance to many organic and inorganic compounds. The chromium content provides resistance to oxidizing environments at high temperatures or in corrosive media, it also resists sulfur compounds.

In high temperature service, Alloy 600 resists oxidation and scaling up to 2000°F (1093°C). It is well suited for applications requiring carburization resistance or in sulfur containing environments at moderate temperatures. However, it is subject to sulfidation at high temperatures.

Alloy 600 is non-magnetic and cannot be hardened by heat treatment, only by cold working. It can be easily welded and processed by standard shop fabrication practices.

Chemical Analysis

Weight % (all values are maximum unless a range is otherwise indicated)

|

|

|

|

|

|

Nickel (plus Cobalt) |

72.0 min. |

Manganese |

1.00 |

|

Chromium |

14.0 min.-17.0 max. |

Sulfur |

0.015 |

|

Iron |

6.0 min.-10.0 max. |

Silicon |

0.50 |

|

Carbon |

0.15 |

Copper |

0.50 |

*Alloy predominates remaining composition. Other elements may be present only in minimal quantities.

Physical Properties

Density

0.304 lbs/in38.42 g/cm3

Specific Heat

0.106 BTU/lb-°F (32-212°F)444 J/kg-°K (0-100°C)

Modulus of Elasticity

31.1 x 106 psi214 GPa

Thermal Conductivity 200°F (100°C)

109 BTU/hr/ft2/ft/°F15.9 W/m-°K

Melting Range

2470 – 2575°F1354 – 1413°C

Electrical Resistivity

620 Microhm-in at 68°C1.03 Microhm-cm at 20°C

|

Mean Coefficient of Thermal Expansion |

|||

|

°F |

°C |

in/in/°F |

cm/cm°C |

|

68 |

20 |

5.8 x 10-6 |

10.4 x 10-6 |

Mechanical Properties

|

Typical Values at 68°F (20°C) |

||||

|

Yield Strength |

Ultimate Tensile |

Elongation |

||

|

psi |

(MPa) |

psi |

(MPa) |

% |

|

35,000 |

(240) |

80,000 |

(550) |

30 |

Corrosion Resistance

Alloy 600 resists corrosion in a variety of environments. Because of the high chromium content of the alloy, it is superior to Nickel 200/201 under oxidizing conditions and its high nickel content enables it to perform well in reducing environments. The presence of nickel also provides excellent resistance to alkaline solutions.

Alloy 600 has moderate resistance to strongly oxidizing acids. However, oxidation occurring in dissolved air alone is not sufficient to insure complete passivity and freedom from attack by air-saturated mineral acids and certain concentrated organic acids.

Heat Resistance

Alloy 600 is used extensively in the thermal processing industry where resistance to oxidation and furnace atmospheres is required. The alloy is also utilized in nitriding applications because of its resistance to nitrogen at high temperatures.

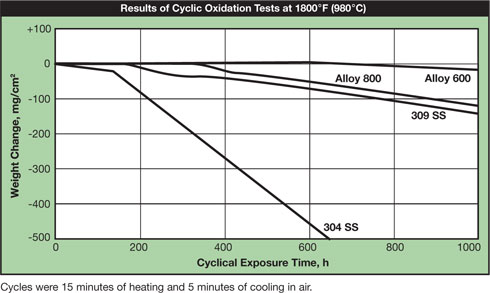

The alloy’s resistance to oxidation and scaling at 1800°F (980°C) is shown in the chart below.

Alloy 600 also has good resistance to carburization per the results of tests in a high temperature carburizing atmosphere.

|

Gas Carbonization Tests (100 h) in Hydrogen/2% Methane |

||

|

Alloy |

Weight Gain, mg/cm2 |

|

|

|

1700°F (925°C) |

2000°F (1095°C) |

|

600 |

2.66 |

12.30 |

|

601 |

2.72 |

16.18 |

|

800HT |

4.94 |

21.58 |

|

330 |

6.42 |

24.00 |

*Atmosphere also conatined 5% argon.

Alloy 600 can be used in sulfur compound service at moderate temperatures, but it is prone to sulfidation in high temperature, sulfur containing atmospheres.

Fabrication Data

Alloy 347 stainless steel plate can be easily welded and processed by standard shop fabrication practices.

Hot Working

The hot-working temperature range for Alloy 600 is 1600 – 2250°F (870 – 1230°C). Heavy working needs to occur between 1900 – 2250°F (1040 – 1230°C), while lighter working can take place down to 1600°F (870°C). The ductility of the alloy is adversely impacted at temperatures between 1200 – 1600°F (650 – 870°C) making it necessary to avoid hot working in this temperature range. High tensile properties can be obtained by careful working at temperatures below 1200°F (650°C).

Cold Forming

Alloy 600 can be cold-formed by the standard shop fabrication practices used carbon and stainless steel. Work hardening rates are greater than mild steel, but less than those of 304.

Welding

Alloy 600 can be readily welded by most standard processes including GTAW (TIG), PLASMA, GMAW (MIG/MAG) and SMAW (MMA). A post weld heat treatment is not necessary. Brushing with a stainless steel wire brush after welding will remove the heat tint and produce a surface area that does not require additional pickling.

Machining

The machinability of Alloy 600 is slightly better than 304, but not as good as 303 free-machining stainless steel. It should preferably be machined in the annealed condition. Since Alloy 600 is prone to work–hardening, only low cutting speeds should be used and the cutting tool should be engaged at all times. Adequate cut depth is necessary to assure avoiding contact with the previously formed work-hardened zone.