Alloy 2507 (UNS S32750) is a super duplex stainless steel with a composition that includes 25% chromium, 4% molybdenum, 7% nickel, and nitrogen. Here are some key features and properties of Alloy 2507:Corrosion Resistance:Alloy 2507 provides exceptional resistance to corrosion, making it suitable for demanding applications in aggressive environments.The high chromium, molybdenum, and nitrogen content contribute to excellent resistance against pitting, crevice, and general corrosion.It has particularly high resistance to chloride-induced stress corrosion cracking (SCC), which is crucial for applications in seawater and chloride-rich environments.Mechanical Properties:Alloy 2507 exhibits high strength, offering excellent mechanical properties.Its high strength allows for the design of lighter structures, reducing weight and cost.Thermal Properties:The alloy has high thermal conductivity, which facilitates efficient heat transfer.It also possesses a low coefficient of thermal expansion, which can be beneficial in certain applications.Alloy 2507 is commonly used in industries such as chemical processing, oil and gas, petrochemical, and seawater equipment. It finds applications in various components, including heat exchangers, pipes, valves, and storage tanks.When using Alloy 2507, it's important to consider specific operating conditions and consult with materials engineers or alloy manufacturers for precise guidance on its suitability, fabrication, and compatibility in particular applications and environments.

Applications

- Oil and gas industry equipment

- Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems

- Chemical process industries, heat exchangers, vessels, and piping

- Desalination plants, high pressure RO-plant and seawater piping

- Mechanical and structural components, high strength, corrosion-resistant parts

- Power industry FGD systems, utility and industrial scrubber systems, absorber towers, ducting, and piping

Standards

ASTM/ASME .......... A240 - UNS S32750EURONORM............ 1.4410 - X2 Cr Ni MoN 25.7.4

AFNOR.................... Z3 CN 25.06 Az

General Properties

Alloy 2304 is a 23% chromium, 4% nickel, molybdenum-free duplex stainless steel. The Alloy 2304 has corrosion resistance properties similar to 316L. Furthermore, its mechanical properties, i.e., yield strength, are twice those of 304/316 austenitic grades. This allows the designer to save weight, particularly for properly designed pressure vessel applications.

The alloy is particularly suitable for applications covering the -50°C/+300°C (-58°F/572°F) temperature range. Lower temperatures may also be considered but need some restrictions, particularly for welded structures.

With its duplex microstructure and low nickel and high chromium contents, the alloy has improved stress corrosion resistance properties compared to 304 and 316 austenitic grades.

Corrosion Resistance

General Corrosion

The high chromium and molybdenum content of 2507 makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid. 2507 also provides excellent resistance to inorganic acids, especially those containing chlorides.

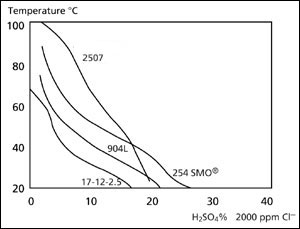

In dilute sulfuric acid contaminated with chloride ions, 2507 has better corrosion resistance than 904L, which is a highly alloyed austenitic steel grade specially designed to resist pure sulfuric acid.

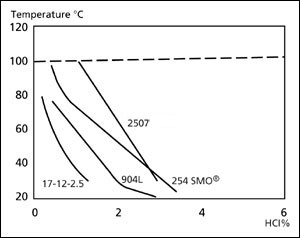

Stainless steel of type 316L (2.5%Mo) cannot be used in hydrochloric acid due to the risk of localized and uniform corrosion. However, 2507 can be used in dilute hydrochloric acid. Pitting need not be a risk in the zone below the borderline in this figure, but crevices must be avoided.

Isocorrosion curves, 0.1 mm/year, in sulfuric acid with an addition of 2000 ppm chloride ions

Isocorrosion curves, 0.1 mm/year, in hydrochloric acid. Broken line curve represents the boiling point

Intergranural Corrosion

2507's low carbon content greatly lowers the risk of carbide precipitation at the grain boundaries during heat treatment; therefore, the alloy is highly resistant to carbide-related intergranular corrosion.

Stress Corrosion Cracking

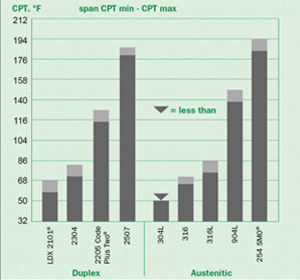

The duplex structure of 2507 provides excellent resistance to chloride stress corrosion cracking (SCC). Because of its higher alloy content, 2507 is superior to 2205 in corrosion resistance and strength. 2507 is especially useful in offshore oil and gas applications and in wells with either naturally high brine levels or where brine has been injected to enhance recovery.Pitting CorrosionDifferent testing methods can be used to establish the pitting resistance of steels in chloride-containing solutions. The data above were measured by an electrochemical technique based on ASTM G 61. The critical pitting temperatures (CPT) of several high-performance steels in a 1M sodium chloride solution were determined. The results illustrate the excellent resistance of 2507 to pitting corrosion. The normal data spread for each grade is indicated by the dark gray portion of the bar.

Crevice Corrosion

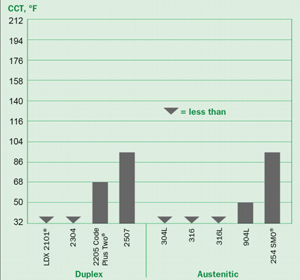

The presence of crevices, almost unavoidable in practical constructions and operations, makes stainless steels more susceptable to corrosion in chloride enviroments. 2507 is highly resistant to crevice corrosion. The critical crevice corrosion temperatures of 2507 and several other high-performance stainless steels are shown above.Chemical Analysis

Typical Values (Weight %)

|

Carbon |

Chromium |

Nickel |

Molybdenum |

Nitrogen |

Others |

|

0.020 |

25 |

7 |

4.0 |

0.27 |

S=0.001 |

|

PREN = [Cr%] = 3.3 [Mo%] = 16 [N %] ≥ 40 |

|||||

Physical Properties

Density

7,800 kg/m3 - 0.28 lb/in3|

Interval |

Thermal |

°C |

Resistivity |

Thermal |

Specific |

Young |

Shear |

|

20-100 |

13 |

20 |

80 |

17 |

450 |

200 |

75 |

|

20-100 |

13 |

100 |

92 |

18 |

500 |

190 |

73 |

|

20-200 |

13.5 |

200 |

100 |

19 |

530 |

180 |

70 |

|

20-300 |

14 |

300 |

105 |

20 |

560 |

170 |

67 |

Mechanical Properties

Mechanical and Physical Properties

2507 combines high tensile and impact strength with a low coefficient of thermal expansion and high thermal conductivity. These properties are suitable for many structural and mechanical components. The low, ambient, and elevated temperature mechanical properties of 2507 sheet and plate are shown below. All of the test data shown are for samples in the annealed and quenched condition.2507 is not recommended for applications which require long exposures to temperatures in excess of 570°F because of the increased risk of a reduction in toughness. The data listed here are typical for wrought products and should not be regarded as a maximum or minimum value unless specifically stated.

Mechanical Properties

|

|

|

|

0.2% Offset Yield Strength, ksi |

80 min. |

|

Ultimate Tensile Strength, ksi |

116 min. |

|

1% Offset Yield Strength, ksi |

91 min. |

|

Elongation in 2 inches, % |

15 min. |

|

Hardness, Rockwell C |

32 max |

|

Impact Energy, ft-lbs |

74 min. |

Low Temperature Impact Properties

|

Temperature °F |

RT |

32 |

-4 |

-40 |

|

Ft-lbs |

162 |

162 |

155 |

140 |

|

Temperature °F |

-76 |

-112 |

-148 |

-320 |

|

Ft-lbs |

110 |

44 |

30 |

7 |

Elevated Temperature Tensile Properties

|

Temperature °F |

68 |

212 |

302 |

392 |

482 |

|

0.2% Offset Yield Strength, ksi |

80 |

65 |

61 |

58 |

55 |

|

Ultimate Tensile Strength, ksi |

116 |

101 |

98 |

95 |

94 |

Values obtained for hot rolled plates (th ≤ 2"). Alloy 2304 must not be used for a long time at temperatures higher than 300°C (572°F), where precipitation hardening phenomenon occurs.

Toughness Values (KCV Minimum Values)

|

Temp. |

-50°C |

+20°C |

-60°F |

+70°F |

|

Single |

75 J/cm_ |

90 J/cm_ |

54 ft. lbs |

65 ft. lbs |

|

Average (5) |

90 J/cm_ |

150 J/cm |

65 ft. lbs |

87 ft. lbs |

Hardness (Typical Values)

|

Average (5) |

HV10 180-230 |

HB : 180-230 |

HRC _ 20 |

Processing

Hot Forming

2507 should be hot worked between 1875°F and 2250°F. This should be followed by a solution anneal at 1925°F minimum and a rapid air or water quench.

Cold Forming

Most of the common stainless steel forming methods can be used for cold working 2507. The alloy has a higher yield strength and lower ductility than the austenitic steels so fabricators may find that higher forming forces, increased radius of bending, and increased allowance for springback are necessary. Deep drawing, stretch forming, and similar processes are more difficult to perform on 2507 than on an austenitic stainless steel. When forming requires more than 10% cold deformation, a solution anneal and quench are recommended.

Heat Treatment

2507 should be solution annealed and quenched after either hot or cold forming. Solution annealing should be done at a minimum of 1925°F. Annealing should be followed immediately by a rapid air or water quench. To obtain maximum corrosion resistance, heat treated products should be pickled and rinsed.

Welding

2507 possesses good weldability and can be joined to itself or other materials by shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), plasma arc welding (PAW), flux cored wire (FCW), or submerged arc welding (SAW). 2507/P100 filler metal is suggested when welding 2507 because it will produce the appropriate duplex weld structure.

Preheating of 2507 is not necessary except to prevent condensation on cold metal. The interpass weld temperature should not exceed 300°F or the weld integrity can be adversely affected. The root should be shielded with argon or 90% N2/10% H2 purging gas for maximum corrosion resistance. The latter provides better corrosion resistance.

If welding is to be done on only one surface and post-weld cleaning is not possible, GTAW is suggested for root passes. GTAW or PAW should not be done without a filler metal unless post-weld cleanup is possible. A heat input of 5-38 kJ/in. should be used for SMAW or GTAW. A heat input of about 50kJ/in. can be used for SAW.