General Properties

Alloys 800H (UNS N08810) and 800HT (UNS N08811) are dual-certifiable Nickel-Iron-Chromium materials that resist oxidation, carburization and other high temperature corrosion. The chemical composition of the two alloys are identical to Alloy 800 (UNS N08800), with the exception of the higher level of carbon present in both grades— (0.05–0.10%) in alloy 800H, and (0.06–0.10%) in alloy 800HT. Alloy 800HT also has an addition of up 1.0 % aluminum and titanium. In addition to the chemistry restrictions, both alloys receive a high temperature annealing treatment that produces an average grain size of ASTM 5 or coarser. The restricted chemical compositions, combined with the high temperature anneal, assure these materials have greater creep and rupture strength when compared to Alloy 800.

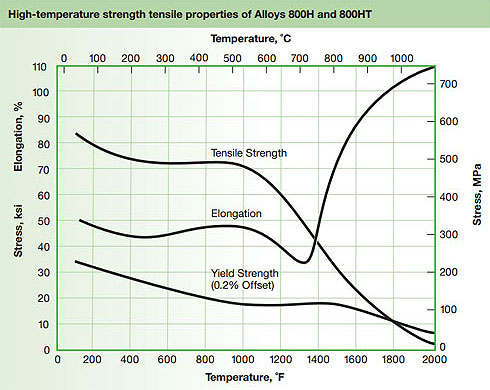

Alloy 800H has good creep-rupture properties at temperatures above 1100°F (600°C). It remains ductile during long term use at temperatures below 1290°F (700°C) due to a maximum titanium and aluminum content of 0.7%. Alloy 800 with a standard anneal is recommended for service below 1100°F (600°C). Alloy 800H resists reducing, oxidizing and nitriding atmospheres, as well as, atmospheres that alternate between reducing and oxidizing. The alloy remains stable in long term high temperature service.

Alloy 800HT has excellent creep strength at temperatures above 1290°F (700°C). If the application involves frequent temperature excursions under 1290°F (700°C) or parts of are permanently exposed to a temperature below 1290°F (700°C), Alloy 800H should be utilized. The high temperature resistance of Alloy 800HT is comparable to Alloy 800H. It also remains stable in long term high temperature service.

Applications

- Chemical and Petrochemical Processing—process equipment for the production of ethylene, ethylene dichloride, acetic anhydride, ketene, nitric acid and oxy-alcohol

- Petroleum Refining—steam/hydrocarbon reformers and hydrodealkylation units

- Power Generation—steam super-heaters and high temperature heat exchangers in gas-cooled nuclear reactors, heat exchangers and piping systems in coal-fired power plants

- Thermal Processing Fixtures—radiant tubes, muffles, retorts and fixtures for heat-treating furnaces

Standards

ASTM..................B 409

ASME..................SB 409

AMS ...................5871

Weight % (all values are maximum unless a range is otherwise indicated)

|

Element

|

800H

|

800HT

|

|

Nickel

|

30.0 min.-35.0 max.

|

30.0 min.-35.0 max.

|

|

Chromium

|

19.0 min.-23.0 max.

|

19.0 min.-23.0 max.

|

|

Iron

|

39.5

|

39.5

|

|

Carbon

|

0.05 min.-0.10 max.

|

0.06 min.-0.10 max.

|

|

Manganese

|

1.50

|

1.50

|

|

Phosphorus

|

0.045

|

0.045

|

|

Sulfur

|

0.015

|

0.015

|

|

Silicon

|

1.0

|

1.0

|

|

Aluminum

|

0.15 min.-0.60 max.

|

0.25 min.-0.60 max.

|

|

Titanium

|

0.15 min.-0.60 max.

|

0.25 min.-0.60 max.

|

|

Aluminum & Titanium

|

0.30 min.-1.20 max.

|

0.85 min.-1.20 max.

|

Physical Properties

Density

0.287 lbs/in3

7.94 g/cm3

Specific Heat

0.11 BTU/lb-°F (32-212°F)

460 J/kg-°K (0-100°C)

Modulus of Elasticity

28.5 x 106 psi

196.5 GPa

Thermal Conductivity 200°F (100°C)

10.6 BTU/hr/ft2/ft/°F

18.3 W/m-°K

Melting Range

2475 – 2525°F

1357 – 1385°C

Electrical Resistivity

59.5 Microhm-in at 68°C

99 Microhm-cm at 20°C

|

Mean Coefficient of Thermal Expansion

Temperature Range

|

|

°F

|

°C

|

in/in/°F

|

cm/cm°C

|

|

200

|

93

|

7.9 x 10-6

|

14.4 x 10-6

|

|

400

|

204

|

8.8 x 10-6

|

15.9 x 10-6

|

|

600

|

316

|

9.0 x 10-6

|

16.2 x 10-6

|

|

800

|

427

|

9.2 x 10-6

|

16.5 x 10-6

|

|

1000

|

538

|

9.4 x 10-6

|

16.8 x 10-6

|

|

1200

|

649

|

9.6 x 10-6

|

17.1 x 10-6

|

|

1400

|

760

|

9.9 x 10-6

|

17.5 x 10-6

|

|

1600

|

871

|

10.2 x 10-6

|

18.0 x 10-6

|

Typicals Values at 70°F (21°C)

|

Yield Strength

0.2% Offset

|

Ultimate Tensile

Strength

|

Elongation

in 2 in.

|

Hardness

|

|

psi (min.)

|

(MPa)

|

psi (min.)

|

(MPa)

|

% (min.)

|

(max.)

|

|

29,000

|

200

|

77,000

|

531

|

52

|

126 Brinell

|

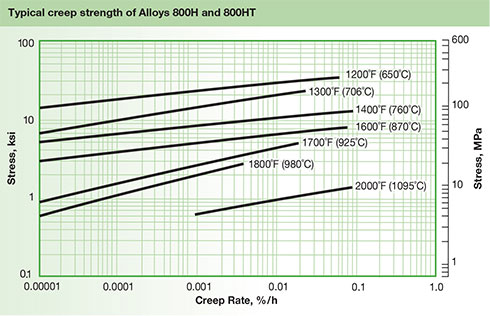

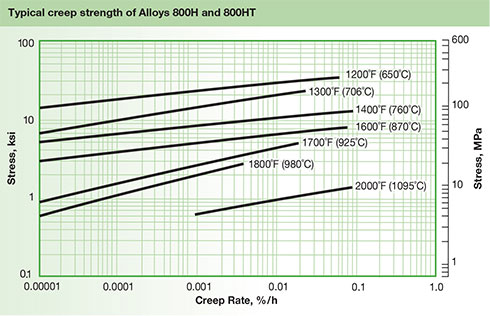

Creep and Rupture Properties

The tight chemistry control and solution annealing heat treatment were designed to provide optimum creep and rupture properties for Alloys 800H and 800HT. The following charts detail the outstanding creep and rupture properties of these alloys.

Representative Rupture-Strength Values for Alloys 800H/800HT

|

Temperature

|

10,000 h

|

30,000 h

|

50,000 h

|

100,000 h

|

|

°F

|

°C

|

ksi

|

MPa

|

ksi

|

MPa

|

ksi

|

MPa

|

ksi

|

MPa

|

|

1200

|

650

|

17.5

|

121

|

15.0

|

103

|

14.0

|

97

|

13.0

|

90

|

|

1300

|

705

|

11.0

|

76

|

9.5

|

66

|

8.8

|

61

|

8.0

|

55

|

|

1400

|

760

|

7.3

|

50

|

6.3

|

43

|

5.8

|

40

|

5.3

|

37

|

|

1500

|

815

|

5.2

|

36

|

4.4

|

30

|

4.1

|

28

|

3.7

|

26

|

|

1600

|

870

|

3.5

|

24

|

3.0

|

21

|

2.8

|

19

|

2.5

|

17

|

|

1700

|

925

|

1.9

|

13

|

1.6

|

11

|

1.4

|

10

|

1.2

|

8.3

|

|

1800

|

980

|

1.2

|

8.3

|

1.0

|

6.9

|

0.9

|

6.2

|

0.8

|

5.5

|

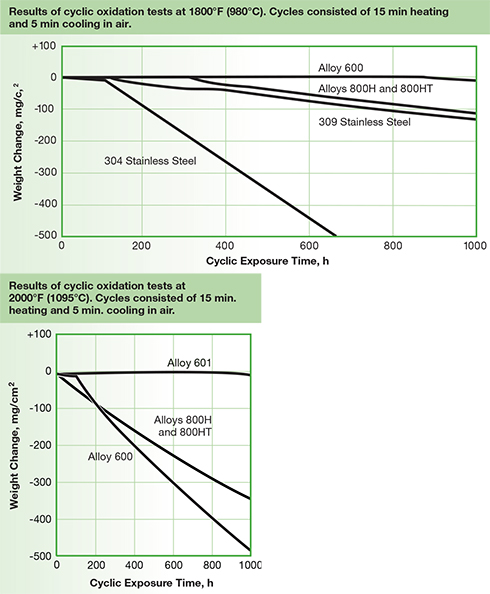

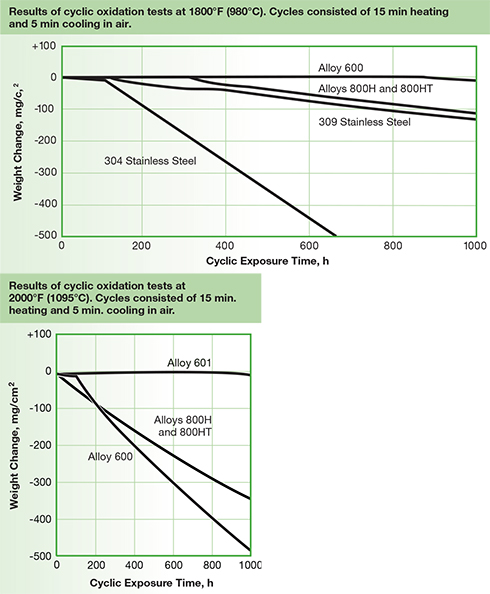

Oxidation Resistance

The combination of the high nickel and chromium content in alloys 800H and 800HT provides excellent oxidation resistance properties to both alloys. The results of cyclic oxidation tests at both 1800°F (980°C) and 2000°F (1095°C) are shown below.

Corrosion Resistance

The high nickel and chromium content of Alloys 800H and 800HT generally means they will have very similar aqueous corrosion resistance. The alloys have corrosion resistance that is comparable to 304 when used in nitric and organic acid service. The alloys should not be used in sulfuric acid service. They are subject to chromium carbide precipitation if in service for prolonged exposure in the 1000-1400°F (538-760°C) temperature range.

Since Alloys 800H and 800HT were developed primarily for hightemperature strength, corrosive environments to which these grades are exposed normally involve high temperature reactions such as oxidation and carburization.

Fabrication Data

Alloys 800H and 800HT can be easily welded and processed by standard shop fabrication practices. However, because of the high strength of the alloys, they require higher powered process equipment than standard austenitic stainless steels.

Hot Forming

The hot-working temperature range for Alloy 800H and 800HT is 1740–2190°F (950–1200°C) if deformation is 5 percent or greater. If the degree of hot deformation is less than 5 percent a hot working temperature range between 1560–1920°F (850–1050°C) is recommended. If the hot working metal temperature falls below the minimum working temperature, the piece must be re-heated. The alloys should be water quenched or rapid air cooled through the temperature range of 1000–1400°F (540–760°C). Alloys 800H and 800HT require solution annealing after hot working to ensure optimal creep resistance and properties.

Cold Forming

The alloys should be in the annealed condition prior to cold forming. Work hardening rates are higher than the austenitic stainless steels. This should be taken into account when selecting process equipment. An intermediate heat treatment may be necessary with a high degree of cold working or with more than 10 percent deformation.

Welding

Alloys 800H and 800HT can be readily welded by most standard processes including GTAW (TIG), PLASMA, GMAW (MIG/MAG), and SMAW (MMA). The material should be in the solution annealed condition, and free from grease, markings or scale. A post weld heat treatment is not necessary. Brushing with a stainless steel wire brush after welding will remove the heat tint and produce a surface area that does not require additional pickling.

Machining

Alloys 800H and 800HT should preferably be machined in the annealed condition. Since the alloys are prone to work–hardening, only low cutting speeds should be used and the cutting tool should be engaged at all times. Adequate cut depth is necessary to assure avoiding contact with the previously formed work-hardened zone.