Products Description

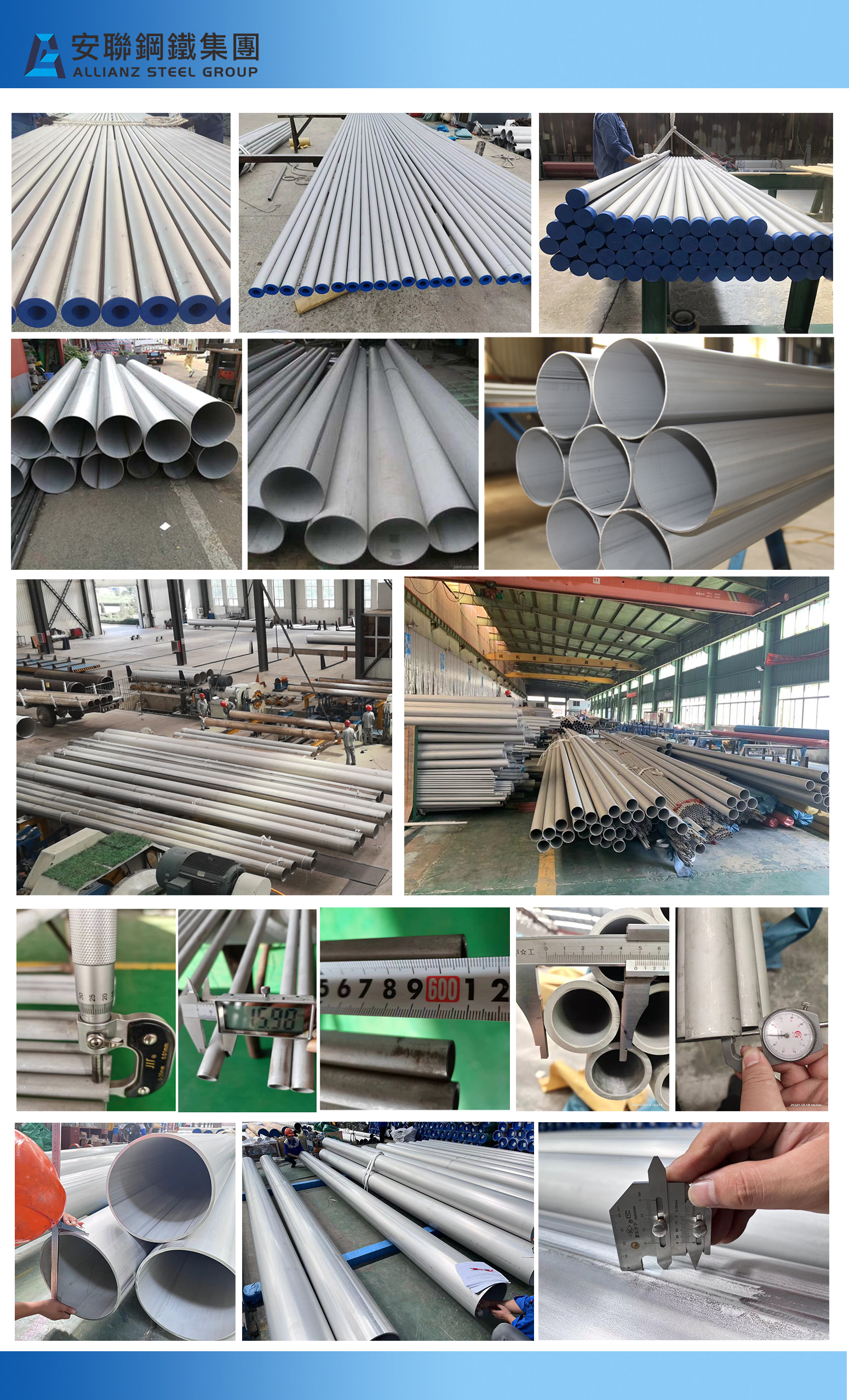

ALLIANZ STEEL GROUP is the leading manufacturer of the SS 304/304L/304H Pipes & Tubes. However, we are supplying and exporting the pipes and tubes to the clients available around the globe. We are also considered among the well-known stockist and importer of the wide ranges of pipes and tubes. The pipes and tubes are available in different specifications as per the expectations of the clients. Specifications like surface finish, end finish, dimensions, shapes, sizes, length, and toughness are there.Pipes and tubes available are interchangeably used in industrial applications. The best way that the industries are distributing fluids among the applications is with the help of the tubular section of the pipes. This is the best to supply all the gas and the fluids which are available. The pipe is the hollow sections which are used in the applications with the round cross-sections that convey the products easily. The dimensions and the diameter of the pipe are noted according to the application in which it is used.Stainless Steel 304 Pipes, SS ASTM A312 TP304L Seamless Pipes, ASTM A213 Stainless Steel 304H Tubes Supplier, SS 304 Welded Tube, ASTM A358 Stainless Steel 304L EFW Pipe Exporter, SS 304H Tubing, Stainless Steel Pipe .Apart from this, the tubes are the pressure equipment that is used in industrial applications. The tubes and pipes are available in many shapes and sizes. Some of the shapes in which the pipes and tubes are available are round, square, rectangle that is having the hollow sections. And the basic difference among the pipes and tubes comes in the wall thickness, material, end connections, and others.

304/304L/304H STAINLESS STEEL PIPES AND TUBES range

|

304 Stainless Steel Pipe & Tubes Specification |

ASTM A269, ASTM A213, ASTM A312, ASME SA269, ASME SA213, ASME SA312 |

|

304 Stainless Steel Pipe & Tubes Grades |

202, 304, 304L, 304H, 304LN, 309S, 310S, 316, 316L, 316H, 316Ti, 316LN, 317L, 321, 321H, 347, 347H, 904L, SMO 254, ALLOY 254, 6MO, 6MOLY, UNS S31254 ETC. |

|

304 Stainless Steel Pipe & Tubes Type |

Seamless / Welded / ERW / EFW / Cold Draw / Hot Finish / Cold Finish |

|

304 Stainless Steel Pipe & Tubes Outer Diameter Size |

Seamless - 1/2" NB TO 18" NB |

|

304 Stainless Steel Pipe & Tubes Wall Thickness |

Schedule 10 to Schedule 160 (3 mm to 100 mm Thickness) |

|

304 Stainless Steel Pipe & Tubes Length |

01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

|

304 Stainless Steel Pipe & Tubes Ends |

Plain Ends / Beveled Ends |

|

304 Stainless Steel Pipe & Tubes Delivery Conditions |

As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw |

|

304 Stainless Steel Pipe & Tubes Coating |

Electropolish, Mechanical Polish, Satin Finish, Passivated |

|

304 Stainless Steel Pipe & Tubes Other Testing |

Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiograph HIC Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

|

304 Stainless Steel Pipe & Tubes Dimension |

All Pipes Is Manufactured and Inspected / Tested to the Relevant standards includingASTM And ASME |

|

304 Stainless Steel Pipe & Tubes Value Added Services |

Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

|

304 Stainless Steel Pipe & Tubes Packaging |

Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

|

304 Stainless Steel Pipe & Tubes Shipment & Transportation |

By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes |

|

304 Stainless Steel Pipe & Tubes Material Test Certificate |

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

304/304L/304H STAINLESS STEEL PIPES AND TUBES EQUIVALENT GRADES

|

STANDARD |

UNS |

WNR. |

AFNOR |

EN |

JIS |

BS |

GOST |

|

SS 304 |

S30400 |

1.4301 |

Z7CN18‐09 |

X5CrNi18-10 |

SUS 304 |

304S31 |

08Х18Н10 |

|

SS 304L |

S30403 |

1.4306/1.4307 |

Z3CN18‐10 |

X2CrNi18-9 / X2CrNi19-11 |

SUS 304L |

304S11 |

03Х18Н11 |

|

SS 304H |

S30409 |

1.4301 |

- |

- |

- |

- |

- |

CHEMICAL COMPOSITION OF STAINLESS STEEL 304/304L/304H SEAMLESS PIPES AND TUBES

|

|

Mn |

Si |

P |

S |

Cr |

Ni |

N |

|

304 |

0.07max |

2.0max |

0.75max |

0.045max |

0.03max |

min: 18.0 max: 20.0 |

min: 8.0 max: 10.5 |

|

304L |

0.03max |

2.0max |

0.75max |

0.045max |

0.03max |

min: 18.0 max: 20.0 |

min: 8.0 max: 12.0 |

|

304H |

min: 18.0 |

min: 8.0 |

min: 0.04 |

0.75 |

2.0 |

0.045 |

0.03 |

MECHANICAL PROPERTIES OF STAINLESS STEEL 304/304L/304H SEAMLESS PIPES AND TUBES

|

Grade |

Tensile Strength ksi (min) |

Yield Strength 0.2% ksi (min) |

Elongation % |

Hardness (Brinell) MAX |

|

304 |

75 |

30 |

40 |

201 |

|

304L |

70 |

25 |

40 |

201 |

|

304H |

75 |

30 |

40 |

201 |

PHYSICAL PROPERTIES OF 304/304L/304H STAINLESS STEEL PIPES AND TUBES

|

SS 304/304L |

||||||

|

Density |

Thermal Conductivity |

Electrical |

Modulus of |

Coefficient of |

Specific Heat |

Melting |

|

at 68°F: 0.285 |

9.4 at 212°F |

28.3 at 68°F |

28 |

9.4 at 32 – 212°F |

0.1200 at 68°F to 212°F |

2500 to 2590 |

|

|

12.4 at 932 °F |

39.4 at 752°F |

|

10.2 at 32 – 1000°F |

|

|

|

|

|

49.6 at 1652 °F |

|

10.4 at 32 – 1500°F |

|

|

|

SS 304H |

||||||

|

Denstiy |

Coefficient of |

Thermal Conductivity BTU/hr-ft-°F |

Specific Heat BTU/lbm -°F |

Modules of Elasticity (annealed)2-psi |

||

|

at 68 °F |

at 68 – 212°F |

at 68 – 1600°F |

at 212°F |

at 932°F |

at 32 – 212°F |

in tension (E) |

|

0.285 |

9.2 |

11.0 |

9.4 |

12.4 |

0.12 |

29 x 106 |

SS 304/304L/304H Pipes & Tubes Application Industries

Our Stainless Steel 304/304L/304H Pipes & Tubes are used in a wide range of applications and various industries. Below are a few of them:

Petrochemical Industry

Oil and Gas Industry

Chemical Industry

Power Plant Industry

Energy Industry

Pharmaceuticals Industry

Pulp & Paper Indusry

Food Processing Industry

Aerospace Industry

Refining Industry

|

304 Stainless Steel Pipe & Tubes Specification |

ASTM A269, ASTM A213, ASTM A312, ASME SA269, ASME SA213, ASME SA312 |

|

304 Stainless Steel Pipe & Tubes Grades |

202, 304, 304L, 304H, 304LN, 309S, 310S, 316, 316L, 316H, 316Ti, 316LN, 317L, 321, 321H, 347, 347H, 904L, SMO 254, ALLOY 254, 6MO, 6MOLY, UNS S31254 ETC. |

|

304 Stainless Steel Pipe & Tubes Type |

Seamless / Welded / ERW / EFW / Cold Draw / Hot Finish / Cold Finish |

|

304 Stainless Steel Pipe & Tubes Outer Diameter Size |

Seamless - 1/2" NB TO 18" NB |

|

304 Stainless Steel Pipe & Tubes Wall Thickness |

Schedule 10 to Schedule 160 (3 mm to 100 mm Thickness) |

|

304 Stainless Steel Pipe & Tubes Length |

01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

|

304 Stainless Steel Pipe & Tubes Ends |

Plain Ends / Beveled Ends |

|

304 Stainless Steel Pipe & Tubes Delivery Conditions |

As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw |

|

304 Stainless Steel Pipe & Tubes Coating |

Electropolish, Mechanical Polish, Satin Finish, Passivated |

|

304 Stainless Steel Pipe & Tubes Other Testing |

Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiograph HIC Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

|

304 Stainless Steel Pipe & Tubes Dimension |

All Pipes Is Manufactured and Inspected / Tested to the Relevant standards includingASTM And ASME |

|

304 Stainless Steel Pipe & Tubes Value Added Services |

Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

|

304 Stainless Steel Pipe & Tubes Packaging |

Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

|

304 Stainless Steel Pipe & Tubes Shipment & Transportation |

By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes |

|

304 Stainless Steel Pipe & Tubes Material Test Certificate |

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

|

STANDARD |

UNS |

WNR. |

AFNOR |

EN |

JIS |

BS |

GOST |

|

SS 304 |

S30400 |

1.4301 |

Z7CN18‐09 |

X5CrNi18-10 |

SUS 304 |

304S31 |

08Х18Н10 |

|

SS 304L |

S30403 |

1.4306/1.4307 |

Z3CN18‐10 |

X2CrNi18-9 / X2CrNi19-11 |

SUS 304L |

304S11 |

03Х18Н11 |

|

SS 304H |

S30409 |

1.4301 |

- |

- |

- |

- |

- |

|

|

Mn |

Si |

P |

S |

Cr |

Ni |

N |

|

304 |

0.07max |

2.0max |

0.75max |

0.045max |

0.03max |

min: 18.0 max: 20.0 |

min: 8.0 max: 10.5 |

|

304L |

0.03max |

2.0max |

0.75max |

0.045max |

0.03max |

min: 18.0 max: 20.0 |

min: 8.0 max: 12.0 |

|

304H |

min: 18.0 |

min: 8.0 |

min: 0.04 |

0.75 |

2.0 |

0.045 |

0.03 |

|

Grade |

Tensile Strength ksi (min) |

Yield Strength 0.2% ksi (min) |

Elongation % |

Hardness (Brinell) MAX |

|

304 |

75 |

30 |

40 |

201 |

|

304L |

70 |

25 |

40 |

201 |

|

304H |

75 |

30 |

40 |

201 |

|

SS 304/304L |

||||||

|

Density |

Thermal Conductivity |

Electrical |

Modulus of |

Coefficient of |

Specific Heat |

Melting |

|

at 68°F: 0.285 |

9.4 at 212°F |

28.3 at 68°F |

28 |

9.4 at 32 – 212°F |

0.1200 at 68°F to 212°F |

2500 to 2590 |

|

|

12.4 at 932 °F |

39.4 at 752°F |

|

10.2 at 32 – 1000°F |

|

|

|

|

|

49.6 at 1652 °F |

|

10.4 at 32 – 1500°F |

|

|

|

SS 304H |

||||||

|

Denstiy |

Coefficient of |

Thermal Conductivity BTU/hr-ft-°F |

Specific Heat BTU/lbm -°F |

Modules of Elasticity (annealed)2-psi |

||

|

at 68 °F |

at 68 – 212°F |

at 68 – 1600°F |

at 212°F |

at 932°F |

at 32 – 212°F |

in tension (E) |

|

0.285 |

9.2 |

11.0 |

9.4 |

12.4 |

0.12 |

29 x 106 |