Stainless Steel Welded Pipe VS Stainless Steel Seamless Pipe

1. Brief Introduction of SS Welded Pipe and SS Seamless Pipe

Stainless steel welded pipe, shorting for welded pipe, is a kind of pipe that commonly welds steel products or steel bands curled and formed by machines and mold. Although the SS welded pipe’s manufacturing technique is effortless and has high production efficiency, various specifications and less equipment investment, its strength is usually lower than SS seamless pipes.

Pic 1: Stainless Steel Welded Pipe

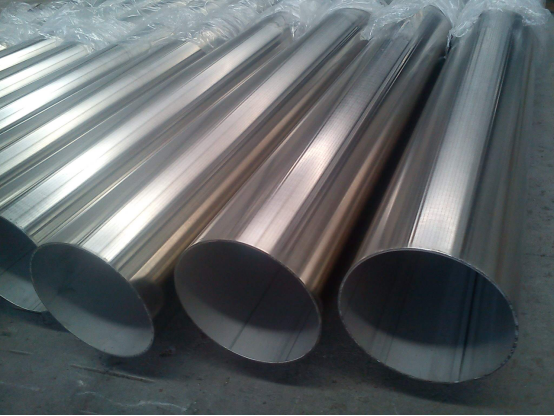

Stainless steel seamless pipe is a long strip of steel product that has a hollow cross-section and no seams around the perimeter. At present, the most use of steel pipes in domestic is stainless steel seamless pipes, which have premium quality but are high in costs and limited in specifications.

Pic 2: Stainless Steel Seamless Pipe

2. Differences Between SS Welded Pipe & SS Seamless Pipe

|

SS Welded Pipe |

SS Seamless Pipe |

|

|

Manufacturing Techniques |

Welding steel products and steel bands that are curled and formed by machines and mold. Welding Methods: longitudinal welded pipe and spiral welded pipe. |

After heating up the round pipe blank, you can produce SS seamless pipes by cold rolling, cold drawing or hot extrusion. |

|

Appearance |

Due to the plate cold forming process, the steel pipe has high precision, uniform wall thickness, high brightness inside the outer surface, and can be arbitrarily sized and rich in size specifications |

The steel pipe has low precision and uneven wall thickness, usually thicker walls. Limited by the processing method, the pipe’s inner surface brightness is low and easy to pit and difficult to remove black spots. And it is costly in size. |

|

Performance |

Since the 1930s, with the rapid development of high-quality strip steel tandem rolling production and improvement of weld and inspection technology, the welding quality advances constantly and the types and specifications of SS welding pipes increased day by day. And in more and more fields, especially in heat exchanger equipment with pipes, decorative pipes, medium and low-pressure fluid pipes, the SS welded pipes replace seamless welded pipes. |

Because of the excellent uniformity of metal organization, SS seamless pipes are mostly used in projects that have high requirements in corrosion resistance, pressure bearing and high-temperature resistance. |

|

Price |

Cheap than SS seamless pipes. |

Expensive than SS welded pipes due to the complicated manufacturing techniques. |

|

|

Due to the awesome pipe surface, it is commonly used as a decorative pipe, prop pipe and more for conveying water, oil, gas, air and low-pressure fluids such as heating water and steam. |

With the premium features of corrosion resistance, pressure bearing and high-temperature resistance, SS seamless pipes are commonly used in engineering and large equipment to transport fluids and can also be used in power stations and nuclear power plant boilers’ containers or pipelines to convey fluids. |